You really don’t want to find out that you needed to clean your heat exchangers due to a system failure.

After all, the regular cleaning and maintaining of heat exchangers is key to keeping your systems running as efficiently as possible. If you’re unfamiliar with what heat exchangers do, no worries. We’ve got your back.

Keep on reading for our basic overview of heat exchangers, and the main three tips you need to know to conduct some essential heat exchanger cleaning.

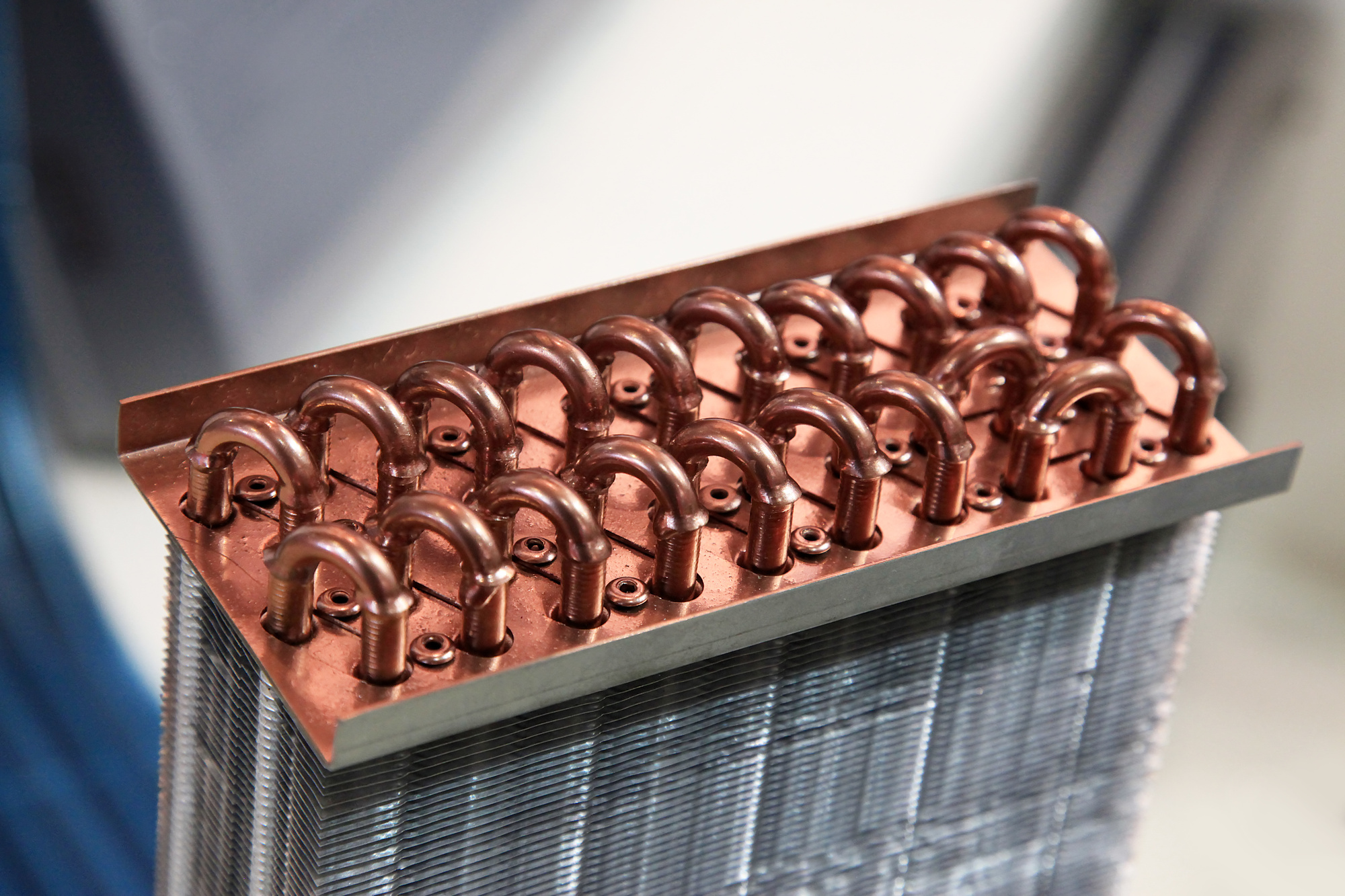

Heat Exchangers 101: What Are We Dealing With Here?

In the simplest of terms, heat exchangers are machines that are designed for optimizing heat transfer from one liquid or gas to another during industrial processing and Clean-in-Place (CIP).

However, as with any sort of machine, it needs regular maintenance and cleaning to function well. When it comes to degraded heat exchanger performance, you’ll start noticing aging or fouling results due to the extra operating and energy costs that compensate for the gaps in the target temperature.

That brings us to the three main ways of getting your heat exchangers cleaned up. However, we’d definitely recommend getting commercial cleaning services to do the job, which will give you better results.

1. The King of Heat Exchanger Cleaning: Chemical Cleaning

One of the most common methods of cleaning heat exchangers would be chemical cleaning. After all, it’s a rather convenient method that doesn’t need you to dismantle the unit from the process.

All you need to ensure is that the unit is taken offline and that the cleaning connections are provided. Also, more likely than not, you’ll have the unit isolated to contain the cleaning fluid.

However, chemical cleaning does have some small drawbacks. The main one has to do with the toxicity of the cleaning fluids, and the difficulty of disposal.

2. Mechanical Cleaning

Of course, you can go old-school and use mechanical cleaning to maintain your heat exchanger’s performance.

However, you’ll need to be aware of the access considerations to physically reach the parts that need some TLC. In addition, the unit will have to be completely removed from the process, so that the servicing can access all parts of the bundles.

3. Vibrasonic Cleaning

The third method you can use to clean heat exchangers would be the perfect mix of the two prior ways. Vibrasonic cleaning mixes the mechanical method with the thoroughness of a cleansing chemical mix.

It works by using pneumatically driven turbines to release sinusoidal wave patterns through a specialized cleaning fluid. This causes mechanical agitation to occur through the chemical liquid, providing a deep and speedy cleaning experience.

Ready to Find the Right Business for the Job?

If you’ve been worrying about learning about the crucial heat exchanger cleaning process, we hope our three key methods of doing so have now left you much better informed than you were before.

The heat transfer process might seem a bit complex at first. But, after reading our little guide, you’re now more familiar with what goes into the process of getting your heat exchangers cleaned up and maintained regularly.

But, there’s still so much more to learn. You can do so by checking out our business resources section for all the tips and tricks you could possibly need.